3 Trends to impact the design of optical payloads for smaller satellites

Behind every beautiful picture, there is more than what the eye meets. For example, many photographers may tell you that their choice of an instrument directly impacts their results. After all, it is the camera that transforms the photons into a picture; if the camera is not on par, the result will also not be. Then again, a good hunter never blames his rifle for a missed opportunity, but a lousy gear choice impacts the story you tell at the end of the day.

The Earth Observation (EO) market is evolving fast, and the various business models of the companies that act across the value chain are driving these changes. We see more companies solving vertical-specific challenges by turning EO information into layers of intelligence and packaging it into user-specific applications. Many of these companies are not even part of the so-called EO Industry, but they all need analysis-ready data that is accessible, interoperable, and ready to fuse with other data sets. After all, they are part of the value chain that creates, delivers, and captures value in this industry.

These datasets do not magically appear. Instead, they are all gathered by platforms hosting instruments that are precision engineered to collect data in extremely harsh environments. This acquisition layer forms the backbone of the EO industry and directly impacts the latest space/satellite/constellation-as-a-service business models we are seeing.

As the competition within this acquisition layer increases, we do see specific trends evolving that have a direct impact on the optical instruments selected, as well as the platforms supporting them. This blog aims to look closely at the three major trends that impact the choice of optical payloads for smaller satellites.

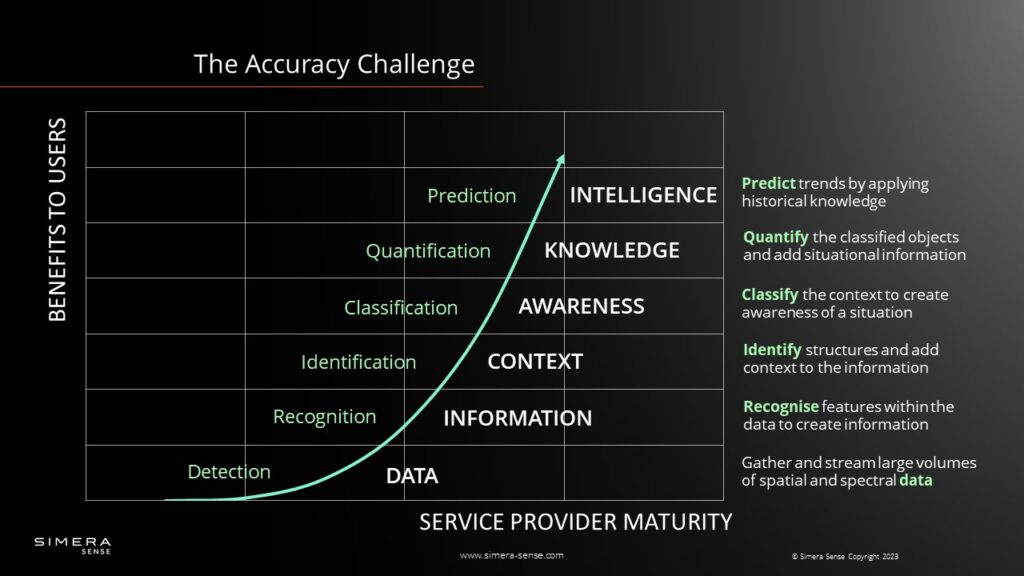

Cost-Benefit vs Accuracy

As piggybacking into space is becoming more popular due to the friendly price tag, we see a tremendous increase in the number of smaller satellites (read nano- and microsatellites) being launched. This trend opened the acquisition layer of the EO value chain to a whole new set of actors. These actors join the party with commercial-driven funding models where the bottom line impacts nearly all decisions. Therefore, overdesigning to squeeze an instrument’s last bit of performance is not more the driver and definitely to on the agenda (it may still be valid for resource-flushed governmental customers). Instead, we are frequently asked, “to what level can you reduce the instrument’s accuracy to lower cost and still address our performance needs?” The question is not about sacrificing performance but finding the best way to reach the optimal cost-benefit vs. accuracy sweet spot.

In many cases, for commercial customers, the figure of merit determining the required performance is poorly articulated, but they may make their desired cost point very clear. Therefore, optical instrument manufacturers must take their customers by the hand and lead them through the minefield of EO instrument and platform trade-offs.

Scaling to meet time-to-market challenges

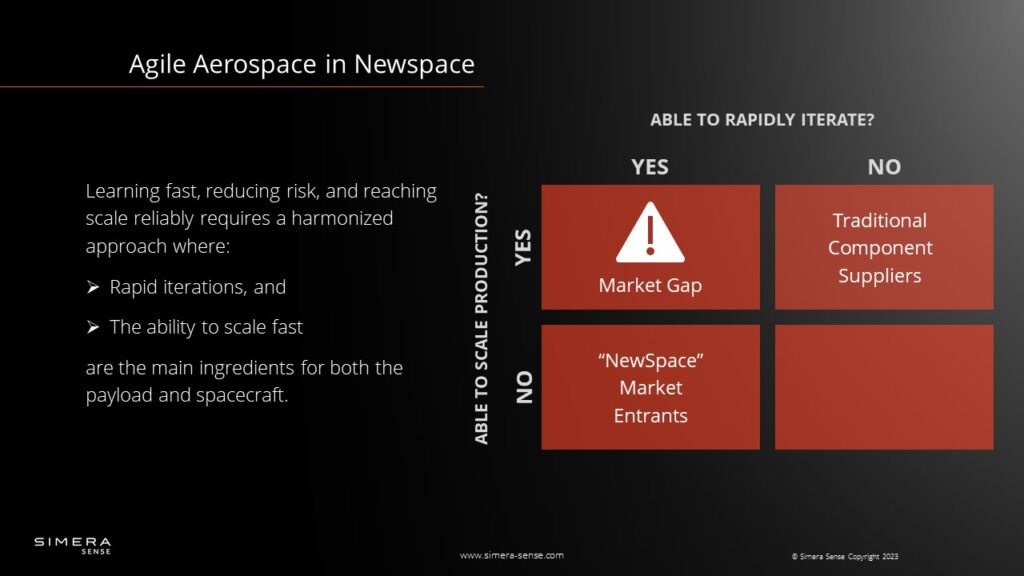

With a commercial-driven mindset, rapidly validating a business model and scaling to reach the proverbial critical tipping point quickly is high on the agenda of any business founder. We all know that traditional optical instrument suppliers are used to working with large budgets and long lead times. As a result, they all want to make the perfect instrument the first time and, in the process, shift the performance beyond what is necessary. Unfortunately, lean methodologies with rapid iterations where you learn from mistakes are not part of their vocabulary.

Furthermore, scaling precision-engineered optical instruments to the numbers required by constellations is also outside the reach of many new entrants in the EO market. It requires reliable supply chains, advanced facilities, and people with specialized knowledge. These resources are difficult to come by and, in many cases, not easily scalable. We all understand, that the market driver to perform quick design iterations and reduce lead times at scale dramatically impacts how we design and manufacture optical instruments.

The traditional way to design, develop, assemble, integrate, and test optical payloads won’t do anymore. The so-called newspace way of doing things requires agile methodologies, where it is all about learning fast, reducing risk, and reaching scale reliably. These principles need to be embedded within the way we think about producing optical payloads.

Minimizing all latencies

We all understand the need for speed. Today, it’s all about the freshness of data and having information at your fingertips. More than that, the growth in unstructured data is outperforming Moore’s Law, forcing organizations to find new ways to transform this constant stream of data into deep insight and deliver value where and when required. In short, we need to work smarter with data.

And this is also true for smaller satellites. Nowadays, a 6U CubeSat with a 5 m GSD multispectral optical instrument can fill up 1 Terabit of onboard storage within a couple of orbits. But, nano- or microsatellites with high-end X-Band transmitters, will still require hours of downlink time to get the data on the ground. Resulting in delays of a couple of days before you can access processed images.

We are long past the stage where the main challenge is to capture large amounts of the globe at the best resolution. Now it is all about getting information into the hands of the decision-makers, and fast. In the words of Henry Ford, everybody wants faster horses, but we all know it is not the smartest solution.

Optical instrument manufacturers and mission operators know the value of reducing data latencies. Therefore, onboard image processing, optical links, and inter-satellite communication are essential topics under discussion when new EO constellations are planned. These topics directly impact how optical instruments are designed and operated. The translation of data into insight and intelligence is not only happening in large server rooms but distributed across the value chain.

Bottom Line

Earth Observation within the newspace industry brings new opportunities and challenges to the table that cannot be solved by our traditional way of thinking when developing optical payloads.

You can contact the Simera Sense team to learn how we use these trends to optimize our optical payloads.