- About / Our facilities

Our cleanroom & optical payload facilities

Simera Sense operates a state-of-the art 600 m² ISO7 certified cleanroom facility, designed for the precise assembly and testing of advanced optical payloads. Furthermore, the facility is secured with full access control, is powered by a dual redundant HVAC system, and supported with complete electrical backup in order to ensure uninterrupted operations.

Every detail, from air purity and temperature regulation to handling procedures, is managed with uncompromising discipline to guarantee the highest standards of quality and consistency throughout production.

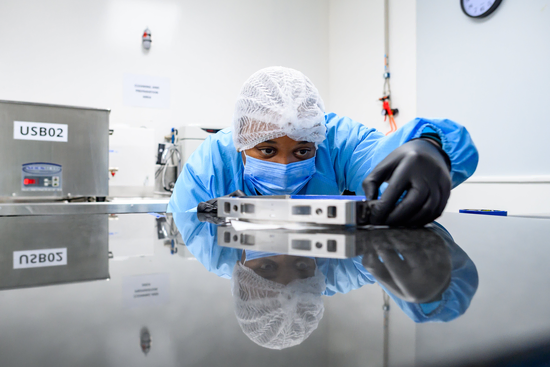

Inside our ISO7 certified cleanroom facility

Our cleanroom enables the precision assembly, alignment, and calibration of high-performance Earth-observation optical payloads.

Air Handling Unit's (AHUs)

Our production facility is equipped with a fully integrated, high-efficiency HVAC system designed to meet strict ISO7 cleanroom standards, thereby ensuring optimal environmental conditions for sensitive operations.

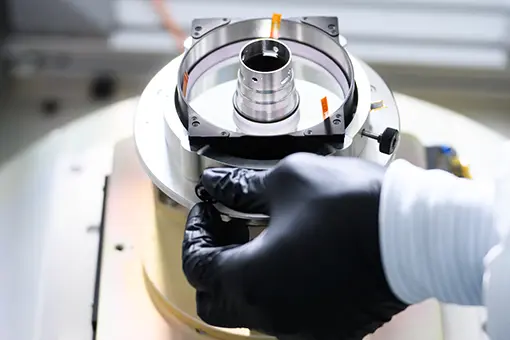

Centration stations

Ensures precise lens alignment within cells by minimising decenter and tilt through optical metrology.

Environmental test facility

Purpose-built facility for thermal and vacuum testing of optical payloads under controlled, space-simulated conditions, with precision data logging.

Vibration table

Impact hammer

Thermal chambers

Thermal Vacuum Optical System (TVOS)

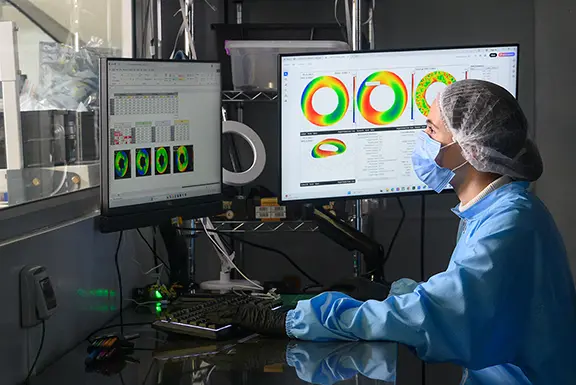

Interferometry facility

High-precision interferometry ensures final lens alignment for minimal aberrations and optimal image quality in front-end assemblies.

Collimation testing facility

Collimator stations enable precise sensor alignment and distortion characterisation to ensure sharp, reliable imaging across all spectral ranges and field positions.

Optics inspection facility

High-precision optical inspection ensures compliance, surface validation, and filter transmittance measurement to meet international quality standards.

Optical quality inspection

Spectrometry

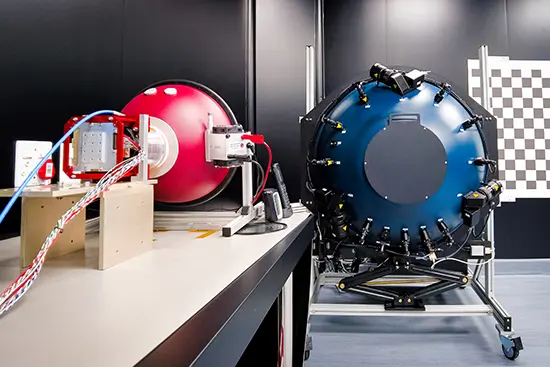

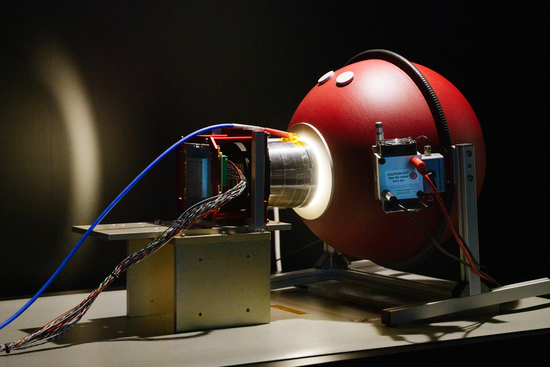

Characterisation facility

Traceable radiometric and geometric characterisation for electro-optical payloads, delivered by a multidisciplinary team of measurement experts.

Parts preparation facility

High-precision optical inspection ensures compliance, surface validation, and filter transmittance measurement to meet international quality standards.

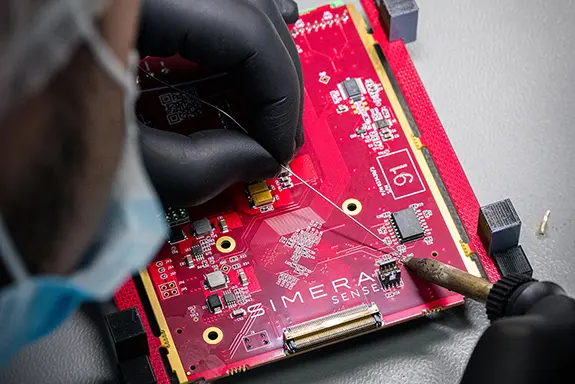

AIT electronics facility

Manual soldering, rework and harness integration by skilled technicians using microscope-enhanced tools for precision electronics assembly.